ADVANCED CAPABILITIES

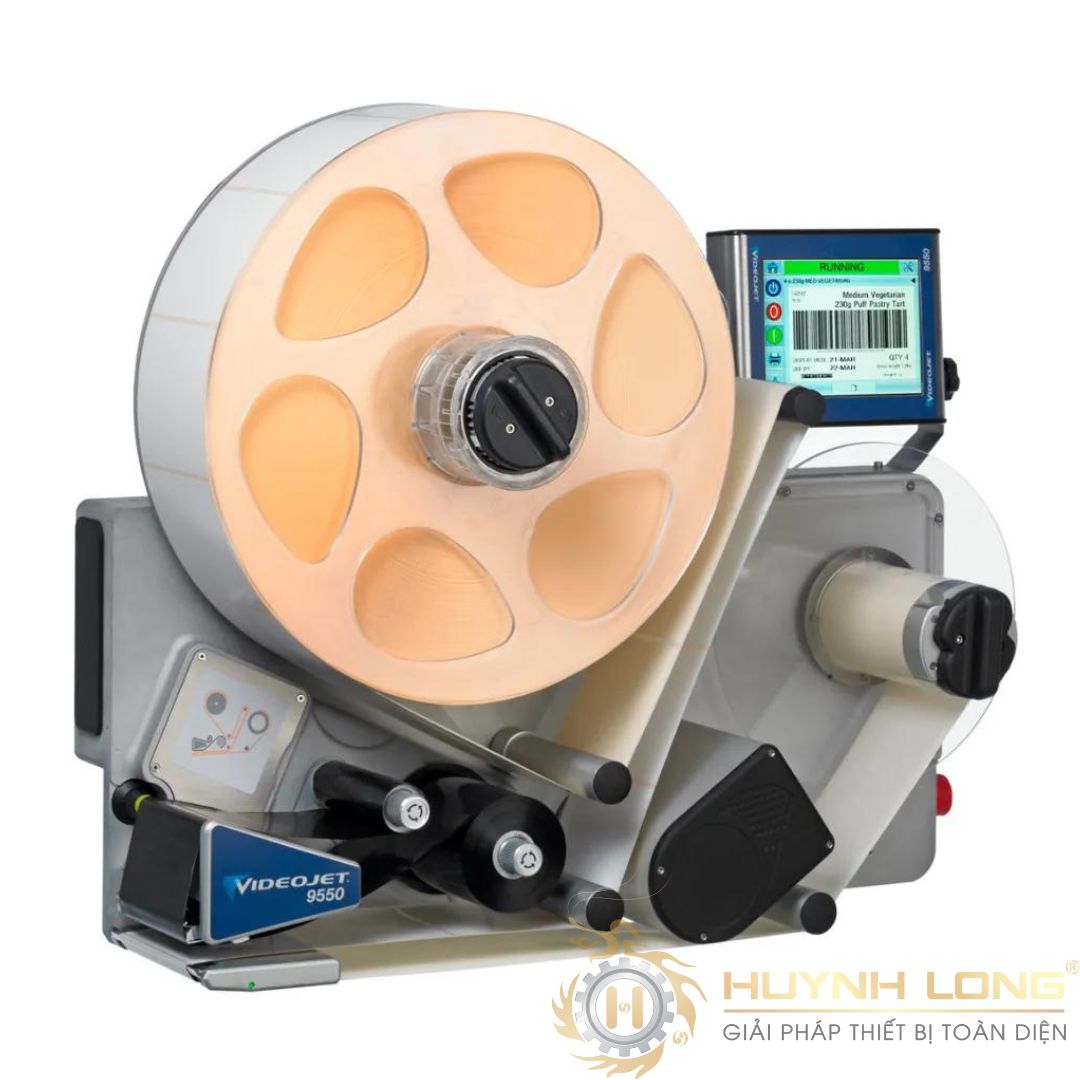

VIDEOJET 9550 with Intelligent MotionTM is a smarter print and apply labeler that targets zero unscheduled downtime and reduces costs and errors in case coding operations. Automatic, precise control of the entire system together with Direct Apply label placement, provides the most efficient and reliable labeling machine.

Uptime Advantage

- Zero mechanical adjustments during day-to-day operation

-

Optimizes maintenance labor by eliminating more than 80% of wear part

- Keep your lines running longer with automatic set-up

Built-in productivity

-

Never miss a label, regardless of line throughput and pack sizes with Direct Apply labeling up to 150ppm for a typical GS1 4”x6” label

-

Optimize print quality and printhead life with automatic printhead pressure regulation

-

Track performance and help achieve OEE improvements with on-screen diagnostics

-

53 mm and 107 mm printhead versions for optimum performance on a wide range of label sizes

Code Assurance

-

Virtually eliminate operator errors, helping to ensure products are coded correctly with built-in Code Assurance software features

-

Minimize operator touches with on-board label database for accurate job selection

-

Automate bar code creation by linking data from multiple text fields

Simple usability

-

Virtually eliminate label jams and simplify set-up with Direct Apply for mainstream top or side applications

-

Minimize misapplied and snapped labels with on-demand Direct Apply using no plant air

-

Perform label and ribbon changes in less than 60 seconds through simplest web path

-

Quickly check status and select jobs with single, intuitive interface that makes operation easy

SPECIFICATION

| Specification | Value |

| Label Application Method | Direct Apply (standard) Other optional applicators: Telescopic tamp, Front of Pack, Rear of Corner Wrap |

| Print Technology | Thermal Transfer printing with Intelligent MotionTM Ribbon Drive or Direct Thermal Printing |

| Ribbon Width | Minimum 53mm width (53mm, 76mm and 110mm standard width ribbons)/Up to 830m |

| Print Resolution | 300dpi (200dpi in emulation mode) |

| Print Speed/ Throughput |

1.6-19.7 inches/sec;Up to 150 packs/min with a 4”x6” label |

| Communications | ZPL, SBPL |

| Label Width/Length/Capacity | 1.6-4.5″/2.0-11.8″/up to 15.7″ spool diameter |

| Interface | CLARiTY Controller – A single intuitive screen with on-board label database and video tutorials |

| Connectivity | Ethernet, RS232, Configurable I/O (24V, PNP and volt free) and USB |

| Certification | CE and TÜV |

APPLICATIONS & VIDEO

Beverage

Cosmetics, Personal and Home Care

Pharmaceutical and Medical Devices

Dairy

Frozen Prepared Meals

Tobacco

Fruits and Vegetables

Additional Applications

- Aero/Auto

- Baked Goods & Cereals

- Meat & Poultry

- Other food

- Pet Food & Animal Feed

- Fish & Seafood

- Salty Snacks

- Egg

- Candy & Confectionery

- Extrusion/Wire & Cable

VietNam

VietNam

Reviews

There are no reviews yet.